Laser cutting is not just used in manufacturing. It also has many other applications in art, architecture, fashion, glasswork, and much more. When it comes to manufacturing, a technique laser cutting dayton oh is used to build cars, aircraft, appliances, boats, and construction equipment to name just a very few. You might be surprised by just how many things that you use every day had at least some of their parts made with the aid of laser cutting. The variety of different types of materials that can be cut using lasers is astounding. They can cut everything from the most fragile paper to thick steel but what exactly is it and how does it work?

Laser cutting is not just used in manufacturing. It also has many other applications in art, architecture, fashion, glasswork, and much more. When it comes to manufacturing, a technique laser cutting dayton oh is used to build cars, aircraft, appliances, boats, and construction equipment to name just a very few. You might be surprised by just how many things that you use every day had at least some of their parts made with the aid of laser cutting. The variety of different types of materials that can be cut using lasers is astounding. They can cut everything from the most fragile paper to thick steel but what exactly is it and how does it work?

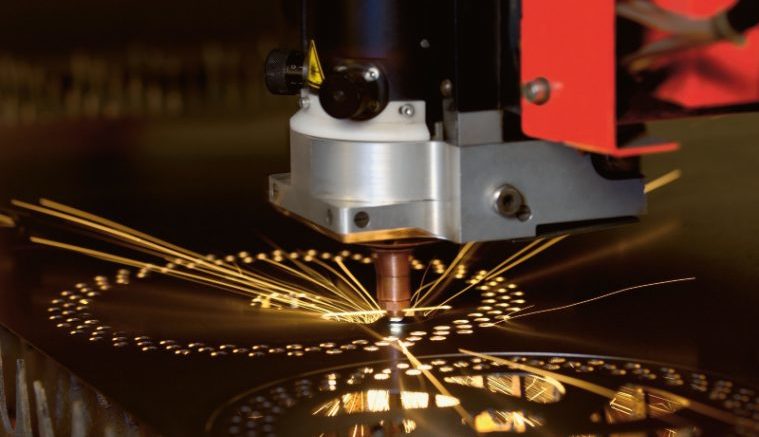

There are different lasers available to cut different material and it’s important that the right equipment is being used for the job or else there could be problems because of it. While the lasers may differ, the way they work is still basically the same. Energy is converted into laser light that is focused into a high-density beam that is highly focused. This beam can then burn, vaporize, or melt whatever is put in front of it with a lot of accuracy.

Laser cutting allows for tiny objects and pieces to be cut with precision which has lowered the cost of many objects. This allows for lower manufacturing costs and these savings can be passed on to the consumer. In addition, the surface that it cuts don’t usually need to go through any more finishing after they have been cut. Other methods can be very time-consuming and comparatively expensive. Laser cutting has allowed some small business to be able to compete with some of the bigger companies in their industries.

The laser beam that is emitted is either a pulsed or continuous wave. Continuous laser beams are known to overheat and pulsed waves allow for this to be avoided in applications such as medical or manufacturing. This means that their operators get the precision of a continuous laser beam without some of the risks associated with it.

There are also differences with how the laser beam moves depending on the machine. In galvanometer machines, the beam is moved by focusing it through a series of mirrors. Because it can cut a lot of material in a short period of time, it is often used in manufacturing processes in bigger companies. The other option involves gantry machines in which the machine itself is moved to focus the beam. The process is slower but great for smaller projects or prototypes.

When compared to ND and ND-YAG lasers, CO2 options tend to be less expensive. Along with manufacturing and welding, these are often used for things such as medical applications to treat skin conditions and cosmetic surgery. For jobs that require more power like drilling, ND-YAG and ND lasers can be used. Like CO2 lasers, they can also be used for welding jobs as well. More and more materials are being cut with lasers and the possibilities seem to be endless.

Some Things You Should Know About Laser Cutting

Be the first to comment on "Some Things You Should Know About Laser Cutting"